Soft Robotic

Fiber-Reinforced Elastomeric Enclosure (FREE)

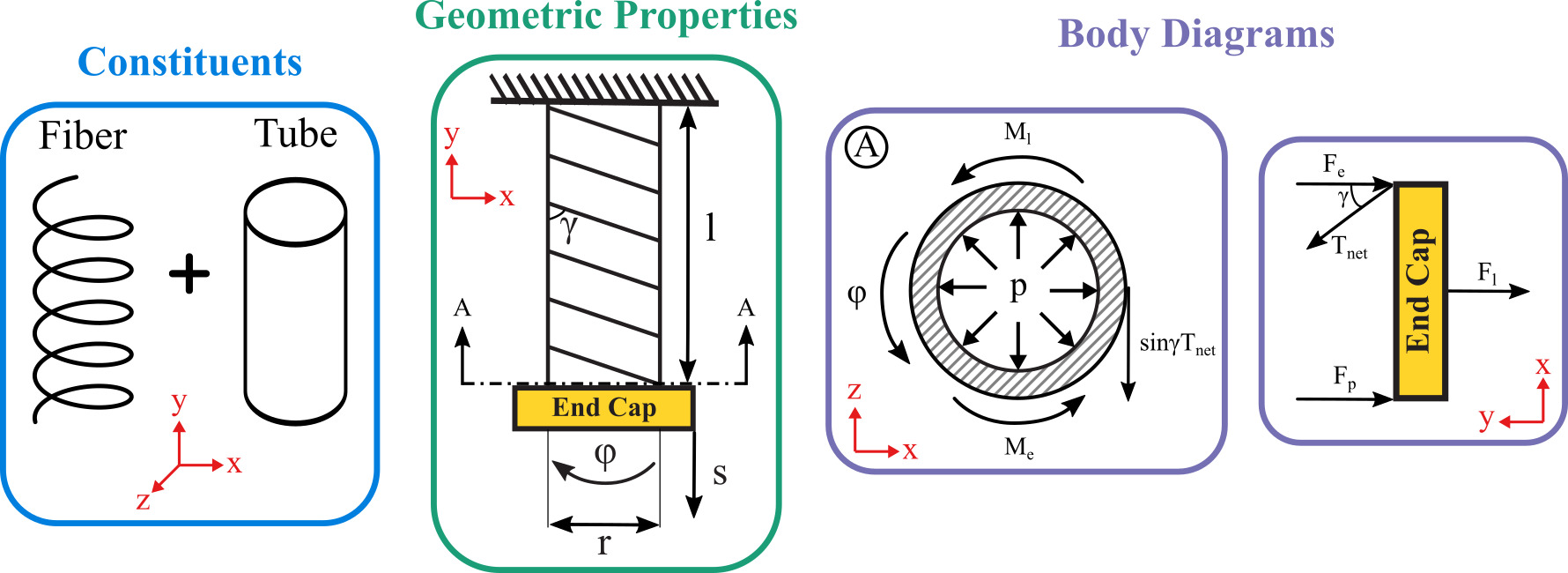

Although robots are increasingly found in a wide range of applications, their use in proximity to humans is still fraught with challenges, primarily due to safety concerns. Roboticists have been seeking to address this situation in recent years through the use of soft robots. Unfortunately, identifying appropriate models for the complete analysis and investigation of soft robots for design and control purposes can be problematic. We sought to address this challenge by proposing two complementary modeling techniques for a particular type of soft robotic actuator known as a Fiber-Reinforced Elastomeric Enclosure (FREE).

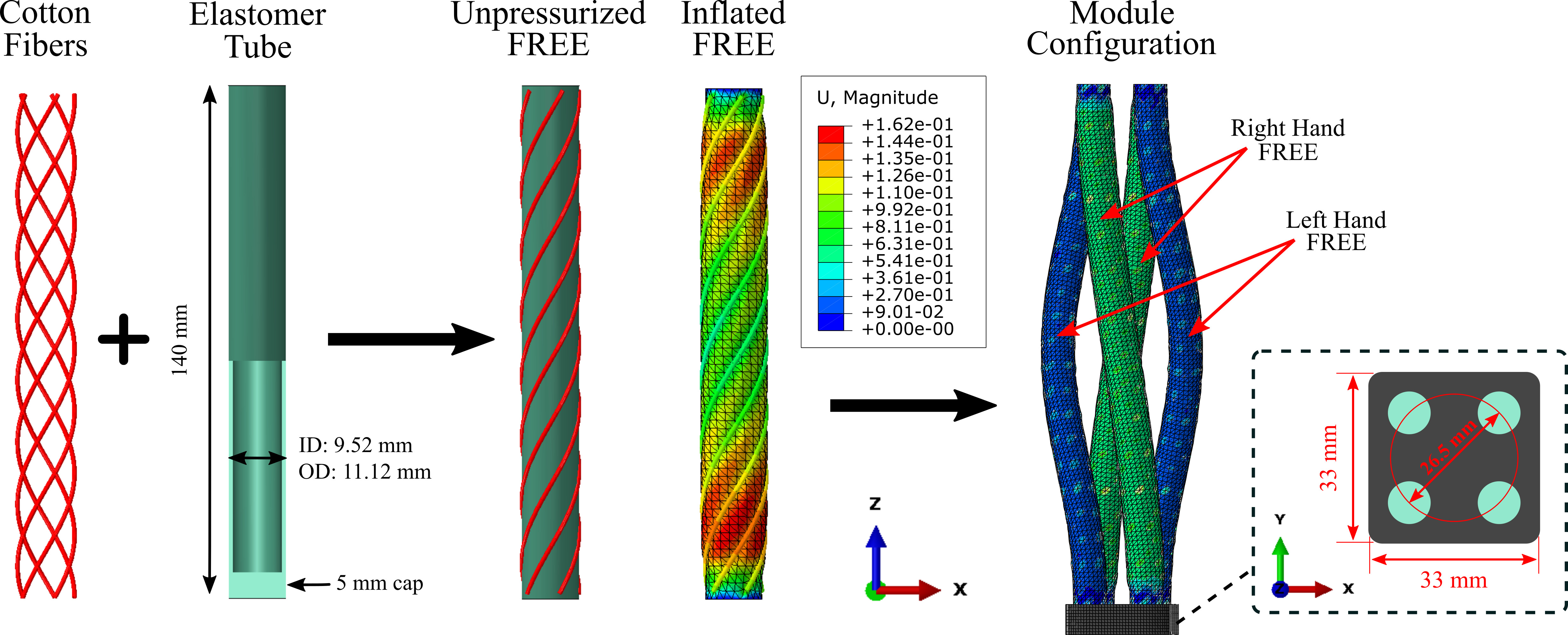

We propose that researchers can leverage multiple models to fill gaps in the understanding of the behavior of soft robots. We present and evaluate both a dynamic, lumped-parameter model and a finite element model to extend understanding of the practicability of FREEs in soft robotic applications.

The results of experimental simulations using a lumped-parameter model show that a linearized, dynamic, lumped-mass model could be successfully used for FREE controller development. Results with the lumped-parameter model demonstrate that it predicts the actual rotational motion of a FREE with at most 4% error when a closed-loop controller is embedded in the system.

We used finite element analysis to study FREE design parameters as well as the workspace achieved with a module comprised of multiple FREEs. Our simulation results indicate that variations in the material properties of the elastic enclosure of a FREE are more significant than variations in fiber properties. We extend our analysis to study the effect of winding angle on FREE force and moment generation. Finally, our finite element results show that a 30-degree difference in winding angle dramatically alters the shape of the workspace generated by four FREEs assembled into a module.